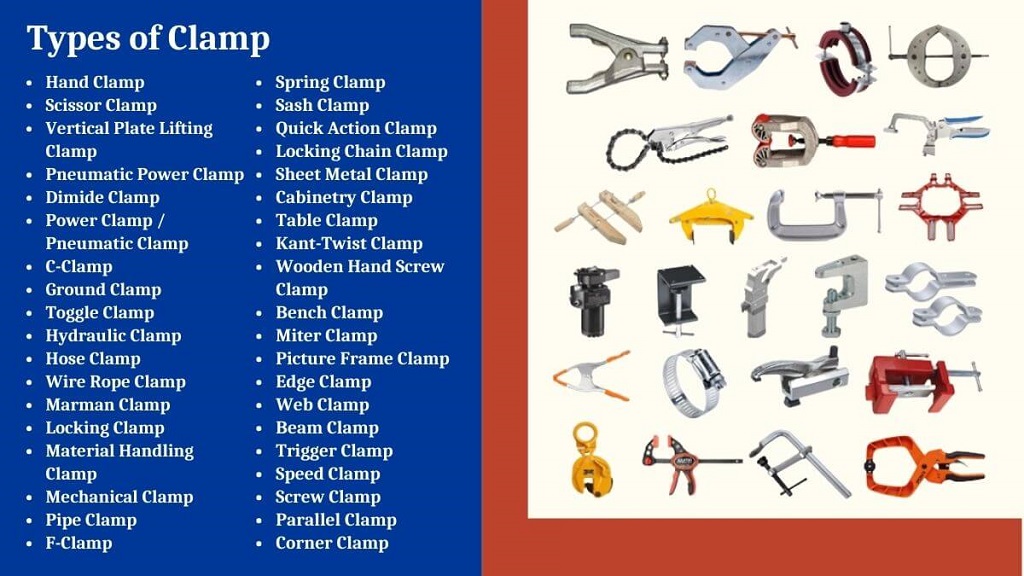

26 Sep How Many Types of Clamps Are Used?

Clamps are essential tools in various industries and DIY projects, offering a secure and reliable way to hold objects together. From woodworking to metalworking, clamps come in a wide range of types, each designed for specific tasks and applications. In this article, we’ll explore the world of clamps and answer the question: how many types of clamps are used?

Understanding the Role of Clamps

Before we explore the different types of clamps, it’s important to understand their fundamental purpose. Clamps are devices that securely grip objects, preventing them from moving or separating during tasks like gluing, welding, cutting, or assembling. They are available in a range of sizes and shapes to suit various applications. If you need a wire rope clamp, consult the wire rope clamp size chart to select the appropriate size for your requirements. Clamps are invaluable tools for guaranteeing accuracy and safety in numerous projects.

Common Features of Clamps

Regardless of their type, clamps share some common features:

- Jaws: All clamps have jaws or gripping surfaces that come into direct contact with the workpiece.

- Adjustability: Many clamps are adjustable to accommodate different sizes and shapes of materials.

- Mechanical Advantage: Clamps use various mechanisms to generate pressure, holding objects securely.

Now that we have a basic understanding of clamps let’s explore the different types available.

Types of Clamps

1. C-Clamps (or G-Clamps)

C-clamps are one of the most common types of clamps and are shaped like the letter “C” or “G.” They have a threaded screw for adjusting the clamp’s opening width and are widely used in woodworking and metalworking.

2. Bar Clamps

Bar clamps, also known as F-clamps, consist of a long bar with a sliding jaw. They are excellent for clamping large workpieces and are commonly used in carpentry.

3. Pipe Clamps

Pipe clamps, as the name suggests, use pipes to create a clamp. They are particularly useful for woodworking projects and provide a high level of clamping pressure.

4. Quick-Grip Clamps

Quick-Grip clamps are known for their speed and ease of use. They are often used in DIY tasks and come with a trigger mechanism for quick adjustments.

5. Spring Clamps

Spring clamps are lightweight and easy to handle. They use spring tension to apply pressure and are suitable for light-duty tasks.

6. Pony Clamps

Pony clamps are small, versatile clamps commonly used for holding materials together during gluing. They are known for their convenience and precision.

7. Toggle Clamps

Toggle clamps are typically used in jig and fixture applications. They have a unique clamping mechanism that allows for quick and secure holding.

8. Parallel Clamps

Parallel clamps, also called cabinet clamps, are designed for cabinetry and woodworking projects. They have parallel jaws that ensure even pressure distribution.

9. Edge Clamps

Edge clamps are specialized clamps used for securing edging and trim materials to workpieces. They provide a strong grip on the edges, preventing any slippage.

10. Band Clamps

Band clamps consist of a band or strap that wraps around the workpiece, applying pressure evenly. They are commonly used in irregularly shaped projects.

11. Miter Clamps

Miter clamps are designed for holding mitered corners in woodworking and framing. They ensure precise alignment during glue-ups.

12. Welding Clamps

Welding clamps are specially designed for welding applications. They provide a secure hold on metal pieces during welding processes.

13. Pneumatic Clamps

Pneumatic clamps use compressed air to generate clamping pressure. They are often used in manufacturing and automation.

14. Corner Clamps

Corner clamps, as the name implies, are used for holding corners at right angles. They are indispensable for creating square joints in woodworking.

15. Hand Screw Clamps

Hand screw clamps are vintage-style clamps with wooden jaws and large screws. They are favored for their aesthetics and function in woodworking.

In conclusion, there are numerous types of clamps available, each tailored to specific tasks and industries. Whether you’re a professional tradesperson or a dedicated DIY enthusiast, having the right clamp for the job is crucial for achieving precision and safety in your projects, just as knowing how to prevent rats from eating car wires is essential for protecting your vehicle’s electrical system.

FAQs

Can clamps be used in welding?

Yes, welding clamps are specially designed for holding metal pieces securely during welding processes.

Are C-clamps and G-clamps the same?

Yes, C-clamps and G-clamps are essentially the same type of clamp and can be used interchangeably.

Which clamp is best for woodworking?

The choice of clamp for woodworking depends on the specific task. However, bar clamps, parallel clamps, and pony clamps are commonly used in woodworking projects.

What are toggle clamps used for?

Toggle clamps are typically used in jig and fixture applications to provide quick and secure holding.

Can band clamps be used for irregularly shaped projects?

Yes, band clamps are suitable for securing irregularly shaped workpieces due to their flexibility and even pressure distribution.

Sorry, the comment form is closed at this time.